CerTa Veritas provides software tools and services for power plant performance issues. Over time, performance degradation by fouling (e.g. in filters and heat exchangers) and mechanical deterioration of components leads to reduced maximum power output and increased heat rate. Timely detection of these issues is essential for timely and effective maintenance, helping to preserve efficiency and minimize operational losses.

Since the deterioration in performance is gradual, the performance depends on the load, and the process variables required for the performance indicators can only be measured with an uncertainty, performance deterioration is not easily detectable by just comparing the current performance with yesterday’s values.

Plant operators are generally most aware about the performance of their main components when the unit is operated in steady state at base load conditions. Certain process variables (such as pressure drops over filters, condenser pressure in relation to cooling water temperature) point them to performance issues of the main components. For this, they rely on the measurement data presented on the DCS operator displays and their professional experience.

However, for units that are being operated under varying (part) load conditions it is much more difficult for the operator to identify if any of the main components is underperforming at the ‘actual’ prevailing conditions.

Nowadays (conventional, large scale) power plants are often operated at varying part load conditions, as the (capacity) share of heavily fluctuating renewable energy sources based on wind and solar radiation in the total power mix has been increased significantly, leading to more varying power production during the day by the conventional plants to balance supply and demand in the grid. This makes it increasingly difficult to detect underperformance. This is especially the case when a measurement of an important process variable does not function properly.

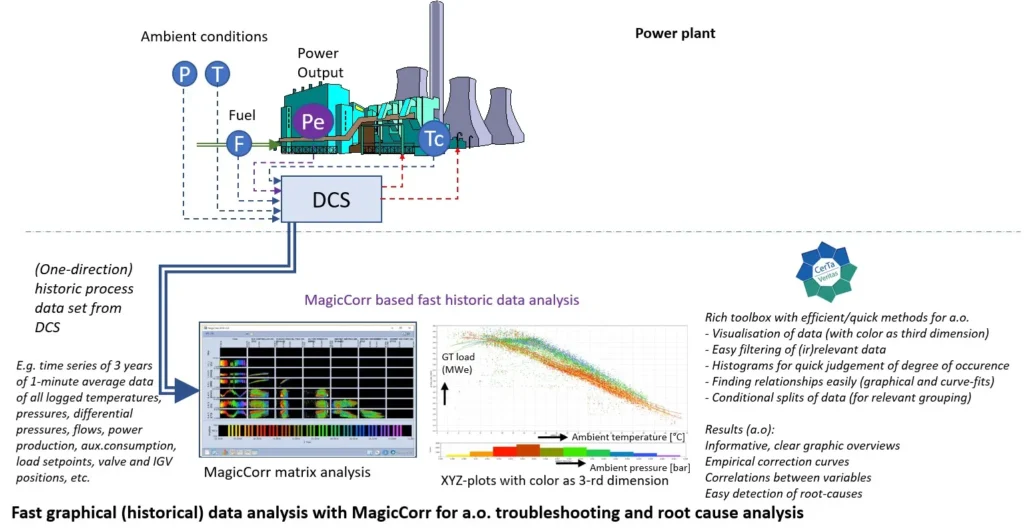

CerTa Veritas has developed software tools which can support the operators and maintenance personnel in identifying possible under-performance issues with main components and correct interpretation of the available measurement data. Furthermore, these software tools can also support the decision makers in carrying out investment analyses.

CerTa Veritas uses these tools on a daily basis for supporting their clients in managing power plant performance. We have compiled our expertise into a white paper presenting three proven approaches for monitoring and analysing power plant performance, illustrated in the figures below:

model-based validation (online of offline) of measurements and performance prediction at actual load case

online performance monitoring by comparing actual performance parameters corrected to site reference conditions to known base line performance parameters

data analysing (historic) measurement data to identify process issues and to provide support in investment decisions

Each of the three above mentioned approaches serve their own specific purpose and are elaborated further in the white paper “Methods and applications to monitor and identify performance related issues for power plants”, available on request.

However, all three approaches have in common that operators get easily insight in actual performance and degradation of their power plant, enabling them to take timely corrective actions, prevent avoidable losses, and reduce operational costs.