Predicting process behavior by thermodynamic modeling and simulation

Power plant owners are continuously seeking ways to improve their assets to make them more efficient, increase capacity and/or reduce environmental impact. All those investment decisions will be based on the expected technical and economic impact they have on the power plant. CerTa Veritas supports decision makers by conducting a study to qualify and quantify the impact on the asset and thus minimize risk. In the situation that new processes have to be developed or existing processes have to be modified, thermodynamic simulation will determine the effects on performance and operability of the power plant. Therefore, a thermodynamic simulation is the basis for feasibility, a design or an improvement study. Investment in process simulation has a good pay-back prospect because it minimizes uncertainties for modification and investment decisions. Process models can also be used in power plant operations to predict the expected performance of the plant starting from the actual or expected site conditions and setpoints, and performance monitoring by comparing of the actual performance with the predicted performance.

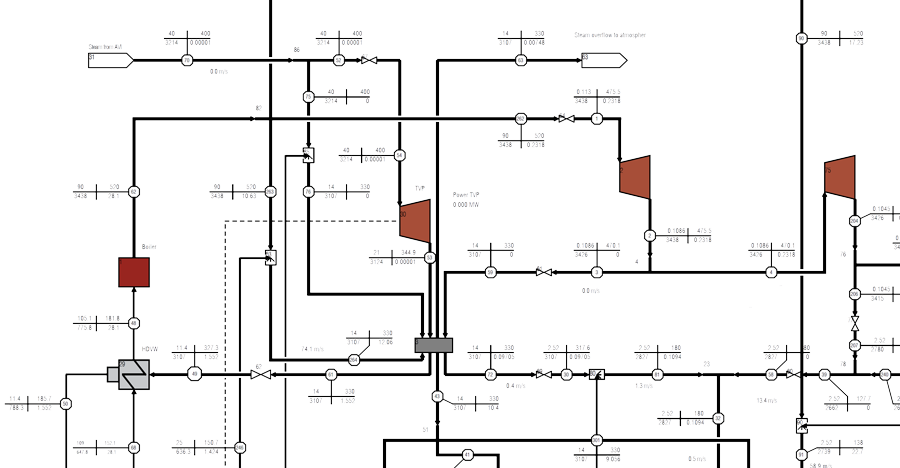

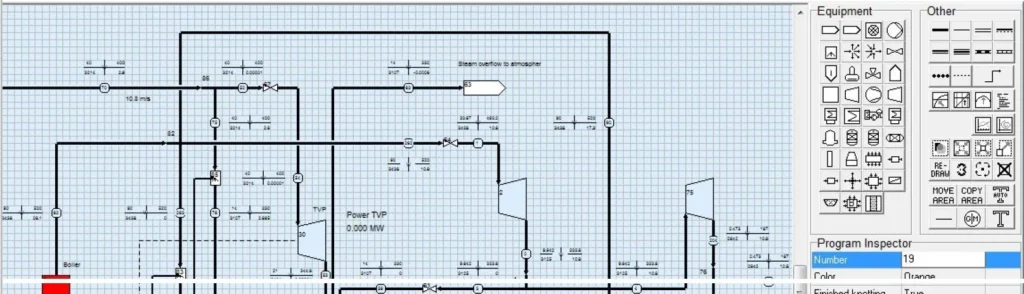

Steady-State Flowsheet Calculations: Power Plants as Modular Systems

At CerTa Veritas, we offer thermodynamic simulation as a stand-alone service to support power plant owners and engineers in enhancing in-house projects. While qualitative knowledge of plant operations is often available, the tools for quantitative process simulations may be lacking. This is where CerTa Veritas adds value, by bridging the gap with proven simulation expertise and powerful tools.

Spence® – A Simulation Tool Built for the Utility Industry

Generating electricity is a highly complex process. Any change, whether in design, fuel composition, or operation, can significantly impact performance. This is especially true for plants using coal, co-firing biomass, or capturing CO₂. Spence® helps power producers understand these impacts clearly and accurately.

Spence® is an open ended, static flowsheet simulator that is especially dedicated for efficient thermodynamic mass and heat balance calculations of thermal power plants. It supports thermodynamic and chemical engineers in their daily work. Spence® is made by process engineers, for process engineers.

Spence® is a powerful and flexible simulation toolbox that models power plant processes in detail. It uses comprehensive libraries containing data on equipment, fuels, gases, particulates, and thermodynamics. When conditions change, such as partial-load operation or fuel variation, Spence calculates the effects throughout the system.

Real-World Application

Spence is widely used in biomass co-firing projects across Canada, the US, the UK, and the Netherlands. It helps determine how fuel shifts affect efficiency and boiler temperature profiles, enabling operators to make informed decisions and avoid costly risks.

Key Benefits of Spence

Tailor-made programming for specific plant needs

Flexible and open-ended: users can add custom libraries

Equipment sizing based on real operating data

Automatic mass and energy balance checks

Graphical flow sheet output with full process conditions (P, T, m, h)

Specialized diagrams including T-s and Q-T charts

Can be expanded into a condition monitoring system